Our Clients

SiteVision AR/MR Universal Phone

Product Dev has worked on a number of occasions with Trimble, a leader in providing positioning solutions to professional industries globally. However, this project was something special. The task was to come up with a design that allowed people to easily visualise their ideas in the real world using AR on their mobile phone with enhanced GPS positioning to 1cm.

Physical 3D printing allowed us to iterate the design quickly making small changes to form factor, which improved the weight, balance and feel of the product. From here, ideas were explored for manufacturing in volume.

An early engagement program using low volume production was undertaken and managed. This allowed the client to test user interaction, quickly prove viability for market and gave them a platform for developing their software/hardware before committing to production tooling.

More info: https://sitevision.trimble.com/

Mobility Power Controller

Product Dev worked with Dynamic Controls to develop the new LiNX product range. This included a new touch screen remote (REM400), which was an industry first. The screen and keypad layout was designed in such a way that it could be used for multiple products.

Product Dev worked in house with a larger team of design engineers using agile methodologies.

MOBILITY POWER CONTROLLER

Product Dev worked with Dynamic Controls to create a new power controller which with greater thermal mass offers 70% improved performance in the same overall package size. The product has a one piece seal which incorporates a number of features into one part. This reduced the number of parts and improved its resistance to vibration and other environmental attacks. Being a high volume product with low margin, new materials and suppliers were used to reduce cost. The modular design allows for 6 product variants from one set of castings.

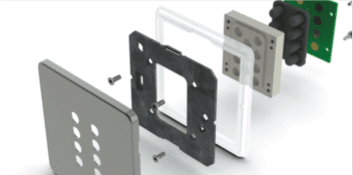

BESPOKE LUXURY ELECTRICAL ACCESSORIES

Product Dev was asked to develop a pushbutton switch plate range for luxury yachts. Product Dev explored methods of switching with the client which reduced overall installation cost and improved reliability in a tough environment. Product Dev used its knowledge of electrical accessories manufacturing, keypad design and modular design to develop a product which allowed for multiple product variants from one set of tooling . This kept the capital investment to a minimum and allowed for a quality bespoke electrical product at a competitive cost.

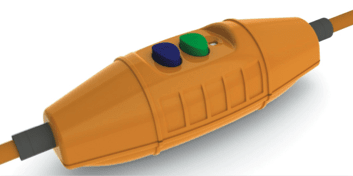

IN-LINE RCD (REWIREABLE)

The RAM Safety Ltd. needed a new product which was easier to wire and assemble than its competitors and that provided foolproof environmental protection. Product Dev benchmarked products in the market place to determine the desirable and undesirable product features and worked with the client to develop a product specification.

Concept layout sketches were generated to determine the ideal product layout.

A functional design was developed in 3D CAD and then prototyped. This new design layout simplified the assembly process and reduced end user installation time significantly.

Further detailed design was carried out to start the hard tooling process. The design was then transferred to a the electrical manufacturer in Asia before it was produced and supplied throughout Europe to high-end tool manufacturers.